Production Line

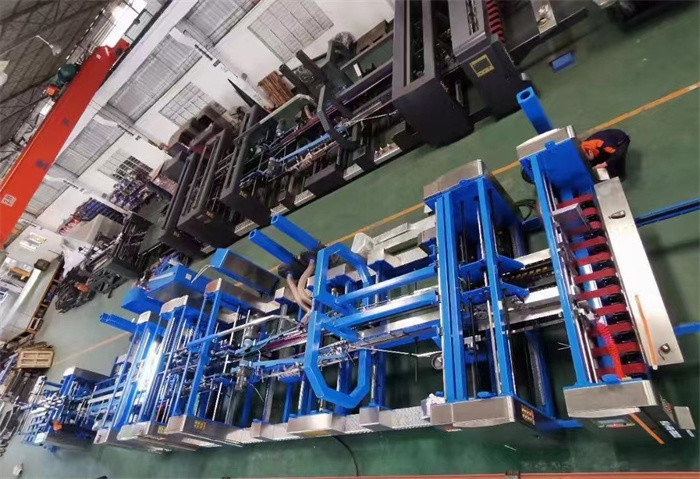

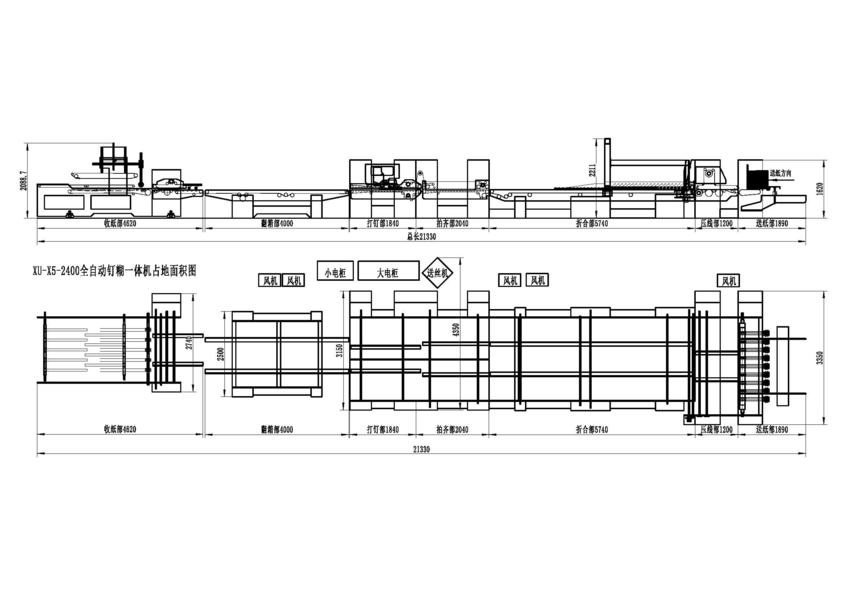

Our production line is a carton back-end process production line which integrate the advanced technology and excellent professionals. Following is an elaborate introduction about the personnel composition and technical equipments, etc. Simply introduce the production line:

1. Professional composition

Experienced masters

They have rich experience in carton production and operation areas and can skillfully deal with various production situations and problems. During the production process, they can ensure the equipments operated steadily and finish the cartons goal in time.

Professional engineers

The engineers have deep professional knowledge an optimized technical background who are responsible for the all production lines design, commissioning and maintenance. They can optimize the production line according to customer requirement and the actual situation to improve production efficiency and quality.

Other professionals

The production line is also equipped with other professionals, such as quality control personnel and equipment maintenance personnel, etc. They are responsible for different responsibilities and jointly ensure the normal operation of the production line and the quality of the cartons.

2. Technical equipment

Advanced production equipment

The Xiangxu nailing machine production line is equipped with the advanced production equipment, including paper feeding unit, creasing/folding unit, shaping unit, nailing/gluing unit,counting unit and discharging unit. These equipments adopt advanced technologies which can achieve the high-speed and stable carton production.

Precision testing instruments

The production line is also equipped with precision testing instruments for strict carton testing. These instruments can ensure that the cartons can achieve customer requirements and relevant standards, improving the product qualification rate and customer satisfaction.

Automatic control system

The production line adopts an automatic control system, which can realize remote monitoring and operation of the equipment. Through the control system, the operating status and production data of the production line can be understood in real time, and problems can be discovered and solved in time which can improve production efficiency and reliability.

3.Other aspects

High flexibility

Our production line has high flexibility and can be quickly adjusted and optimized according to customer needs and the actual situation. This enables the production line to adapt to the production of cartons of different specifications and materials, to meet the needs of different customers.

Perfect after-sales service

Providing customers with perfect after-sales service, including equipment installation and commissioning, operation training, equipment maintenance, etc. This can ensure that customers receive technical support in time during use, improving customer satisfaction and loyalty.

In summary, our production line integrates advanced production equipment, professional technicians and precision testing instruments, proving high flexibility, reliability and perfect after-sales service.

OEM/ODM

When we produce machines, we can fully meet customers' customized requirements for machine color, carton production specifications, carton production speed, etc. The following is a detailed interpretation of these customized requirements:

1. Machine color customization

We provide customized services for machine colors. Customers can choose suitable color for customization according to their preferences or the needs of the production environment. This customized service not only meets the personalized needs of customers, but also makes the machine more coordinated and beautiful in the production environment.

2. Customization of carton production specifications

Diversified specifications: We can customize carton production specifications according to the carton size, shape and other requirements provided by customers. This customized production method ensures that the carton can fully meet the actual needs of customers.

High-precision production: During the production process, we use advanced processes and technologies to ensure the accuracy and stability of the cartons. Whether it is a simple rectangular carton or a complex special-shaped carton, high-precision and high-quality production can be achieved.

3. Customization of carton production speed

Efficient production: Our production line has efficient production capacity and can adjust the speed according to the customers production needs. Customers can choose the appropriate production speed for customization according to their production plan and order quantity.

Flexible adjustment: Each unit and equipment on the production line has the ability to be flexibly adjusted, they can be quickly adjusted and optimized according to the actual needs of customers. This flexibility ensures that the production line can adapt to the cartons production of different specifications and materials, while meeting the production speed requirements of different customers.

4. Other customized services

In addition to the above customization requirements, we also provide a variety of other customized services, such as the selection of carton materials, the design of carton printing patterns, etc. These customized services enable customers to customize in all aspects according to their actual needs, thereby meeting more diversified production needs.

In summary, when we produce nail glue machines, we can fully meet customers' customized requirements for machine color, carton production specifications, carton production speed, etc. This customized production method not only meets the personalized needs of customers, but also improves production efficiency and quality, creating greater value for customers.

R&D

The Design and Development Department plays a core role in transforming ideas into real products. The department brings together talents from different design backgrounds and professional skills, including industrial designers, software developers, user experience experts, structural engineers, etc., they work together to ensure that every detail of the product is beautiful and practical.

During the design stage, team members will conduct in-depth research on market demand, user behavior and competitive product analysis, and use this as a basis to conceive innovative and brand-oriented design solutions. Later, during the development process, they will use advanced technologies and tools to transform design concepts into physical products or digital solutions. This process involves not only the design of the product appearance, but also functional implementation, performance optimization, cost control and other aspects.

The Design and Development Department is also responsible for the continuous optimization of existing products. By collecting user feedback and data analysis, it continuously iterates and upgrades to improve the competitiveness and user products experience.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!